On this page are presenting some examples of application using kinetic schemes developed at CERFACS with a non-exhaustiv list of publications related to the chemistries used (complete list available on CERFACS website).

1. Different fuels

a) H2 chemistries

Roadmap for the EU include the targe of zero-net CO2 emissions by 2050, which is tantamount to the decarbonation of energy. “e-fuels” are considered as a solution to achieve this goal, which includes dihydrogen (H2), ammonia (NH3) or methane (CH4). However, as these fuels burn very differently from commonly used petroleum-derived fuels such as diesel or kerosene, work is needed to ensure the safety and the pollutants reduction.

More information on the general strategy are provided here.

Agostinelli, P. W.. Assessment of Large Eddy Simulation in the Conjugate Heat Transfer context for engine operability: application to Hydrogen enrichment and Spinning Combustion Technology. PhD Thesis. Ecole doctorale MEGEP – CERFACS. 4 (2022).

b) Sustainable Avation Fuels (SAFs)

“e-fuels” mentionned earlier such as dihydrogen requires a complete change of the engine and are therefore considered as a long-term solution. As a short-term solution, the use of drop-in alternative fuels or Sustainable Aviation Fuels (SAFs) is necessary to reduce the carbon footprint of the transportation sector. Indeed, even though the molecules used to create those SAFs are heavy hydrocarbons as conventional fuels, their resulting pollutant reduction comes from the CO2-capture of the feedstock that decreases the total life cycle emission. To simulate those SAFs accurately, precise chemistry and liquid data as well as the right modelling are required and tackled in the work done at CERFACS.

Irimiea, C., Vincent – Randonnier, A., Dufitumukiza, J. P., Puggelli, S., May – Carle, J. B., Treleaven, N. C. W., Lesaffre, T., Coudray, A., Lameloise, E., Cuenot, B., Riber, E., Fdida, N., Cherubini, P. and Mercier, X. (2022) ALTERNATE: Experimental and modeling study of soot formation in high-pressure kerosene and SAF combustion, TSAS2022 – 15th Towards Sustainable Aviation – Toulouse, France, 18-20 October. 2022

Wirtz, J.. Modelling the impact of fuel in aeronautical gas turbines. PhD Thesis. Cerfacs. (2022).

Shastry, V.. Simulation of multicomponent spray combustion in gas turbine engines. PhD Thesis. Ecole doctorale MEGEP – CERFACS. 3 (2022).

Cazères, Q.. Analysis and reduction of chemical kinetics for combustion applications. PhD Thesis. Université de Toulouse III -INP Toulouse : MEGeP. 7 (2021).

c) Oxycombustion

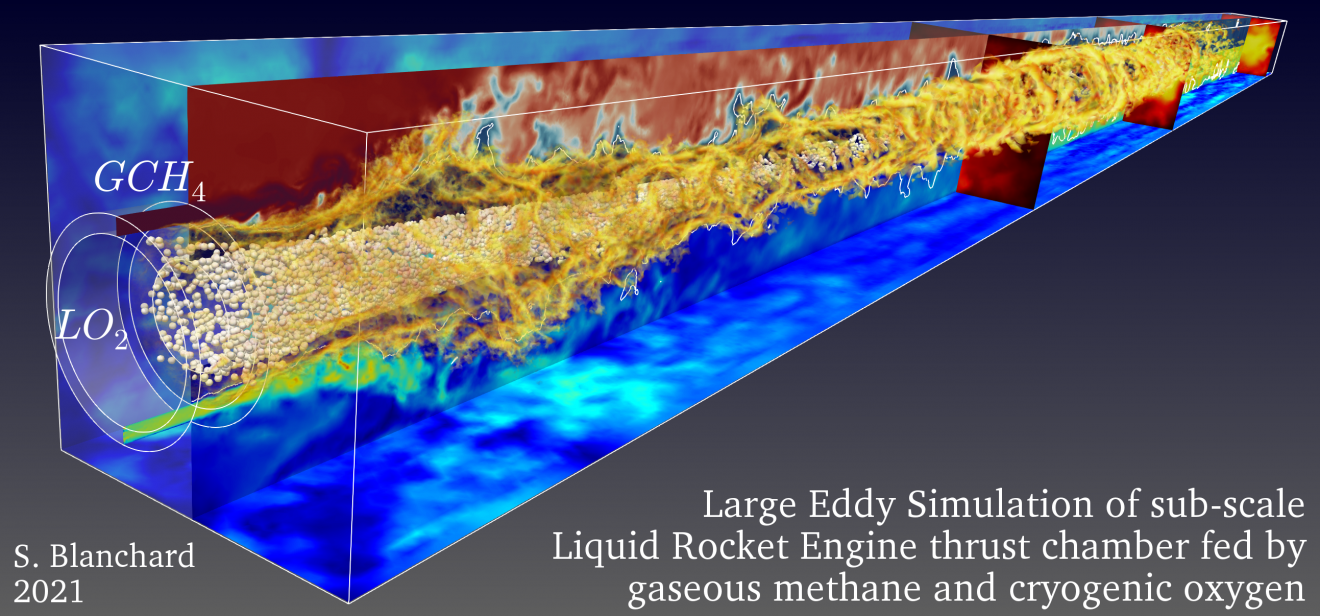

Oxycombustion is an important matter when dealing with rocket-engines and furnaces. In the first case, as the power released should be maximised in a small amount of time, pure oxygen is a solution. In the second case, making glass with a higher efficiency and lower pollutant emissions, enriched oxygen is suggested as a solution. However, flames involving pure oxygen are very fastly reacting and require work on chemistry.

Blanchard, S.. Multi-physics large-eddy simulation of methane oxy-combustion in liquid rocket engines. PhD Thesis. Ecole doctorale MEGEP – Dynamique des fluides – CERFACS. 9 (2021).

d) Plasma

Plasma assisted combustion is a promising solution for improving the engine performance and reduce the emissions by enabling the use of leaner operating point. However, the chemical schemes developed remain complex since they must integrate the interaction of reactants and intermediate species with ions. Furthermore, the movement of the electrons is very fast, offering a wide span of timescales that must be represented in a burner.

Barleon, N.. Detailed modeling and simulations of Nanosecond Repetitively Pulsed Discharges for Plasma-Assisted Combustion (PAC). PhD Thesis. Cerfacs. (2022).

Cheng, L.. Detailed Numerical Simulation of Multi-Dimensional Plasma Assisted Combustion. PhD Thesis. Ecole doctorale MEGEP – CERFACS. 2 (2022).

e) Steam cracking processes

Nadakkal-Appukuttan, S.. Large Eddy Simulation of the steam cracking process in refinery furnaces. PhD Thesis. Ecole doctorale MEGEP – CERFACS. (2022).

Campet, R.. Simulation and optimization of steam cracking processes. PhD Thesis. Université Fédérale de Toulouse, INPT – Ecole doctorale MEGeP. (2019).

2. Pollutants

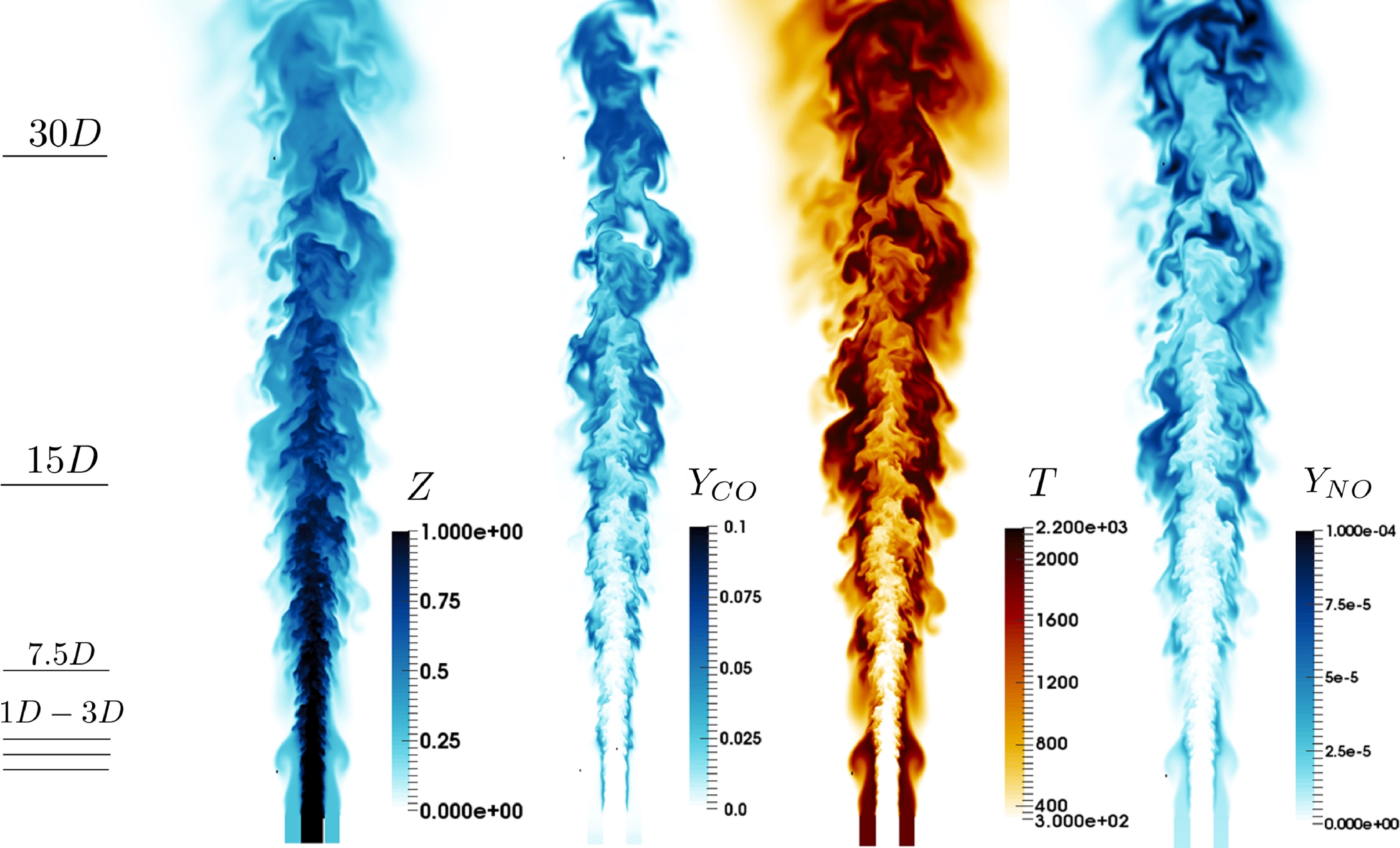

a) NOx predictions

Among the pollutants that engine designers have to look at, NOx emissions are to be considered. Indeed, even though they are release in small amount, they are highly dangerous and released in the higher atmosphere. The precise chemistry required to simulate those species and the long consumption time are the two challenges remaining to correctly predict the emissions.

Jaravel, T.. Prediction of pollutants in gas turbines using Large Eddy Simulation. PhD Thesis. Université de Toulouse – Ecole doctorale MEGeP. 4 (2016).

b) Soot predictions

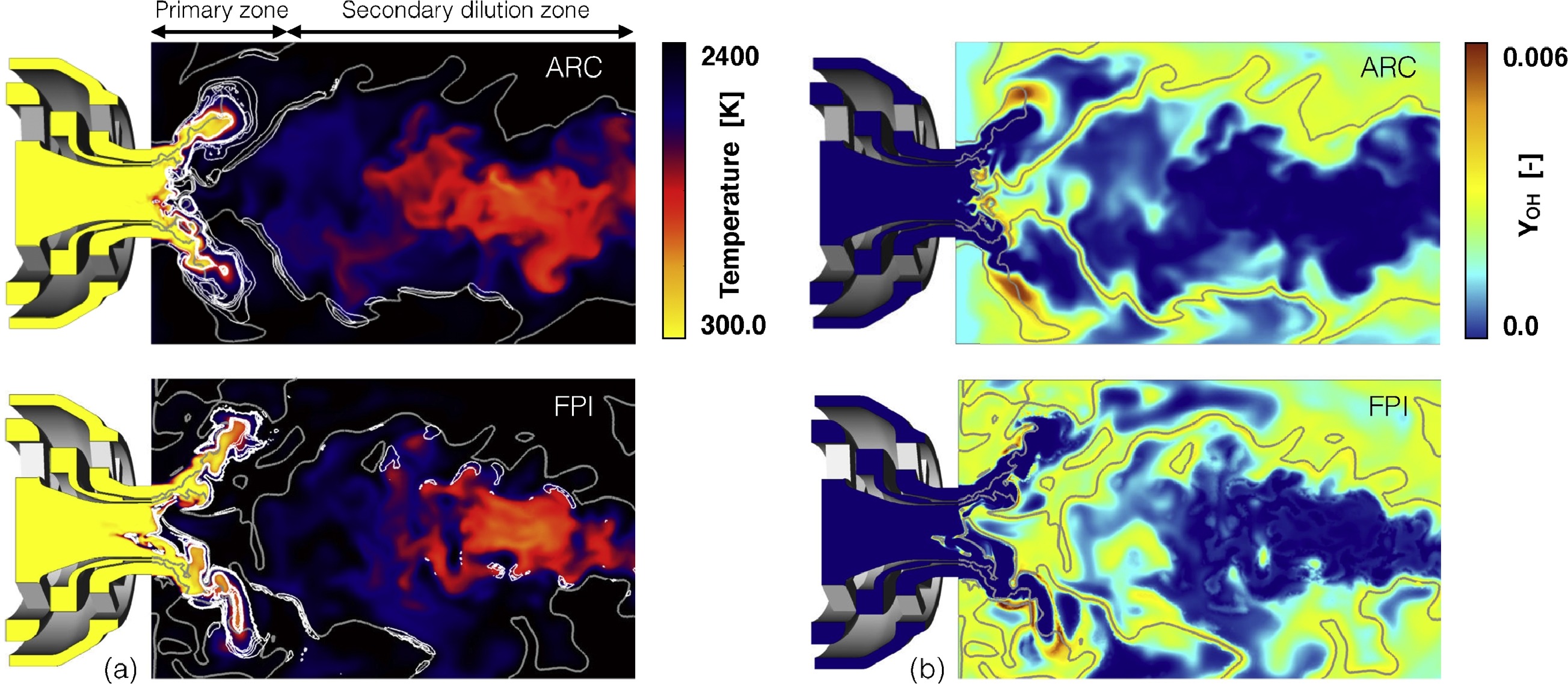

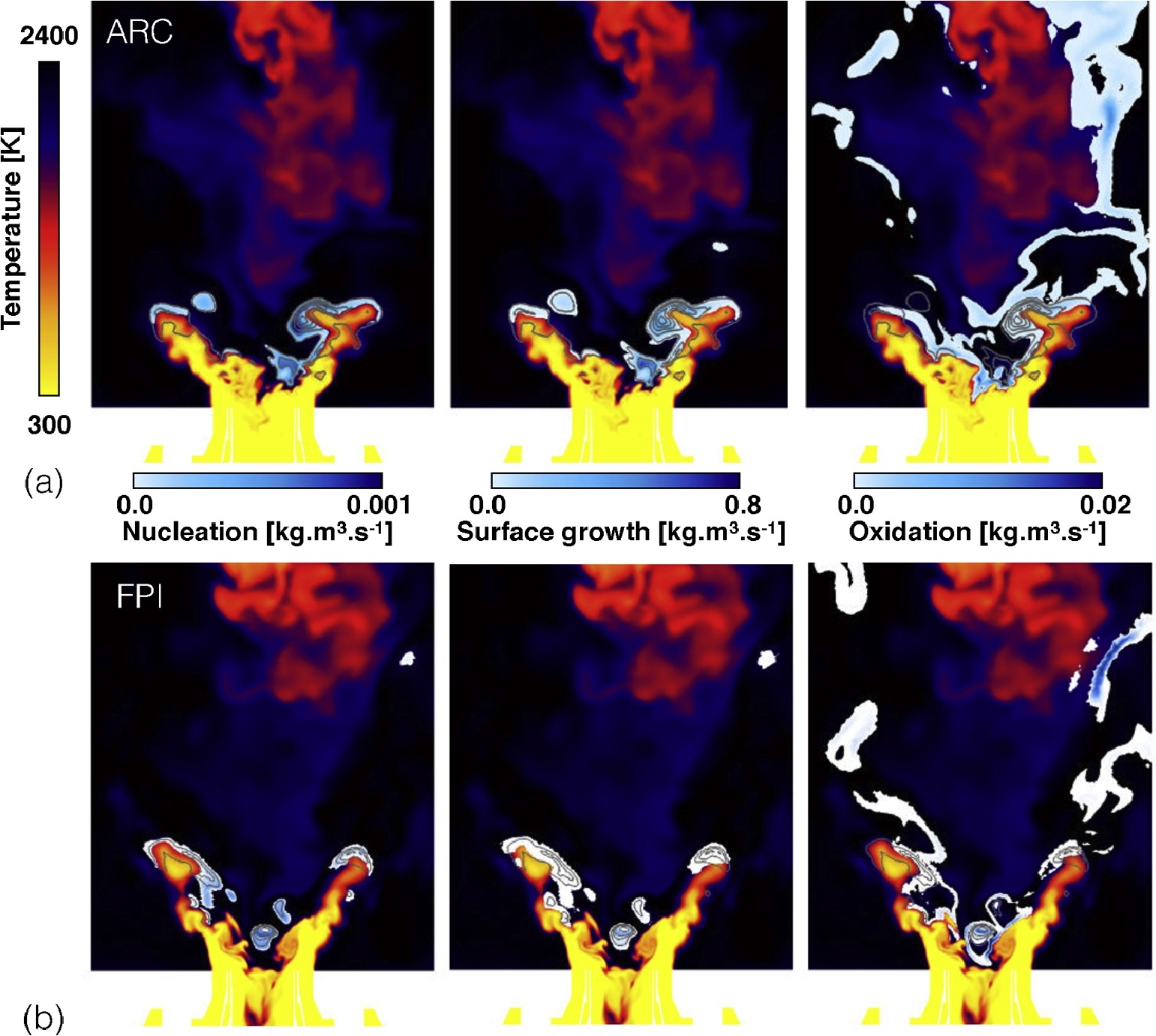

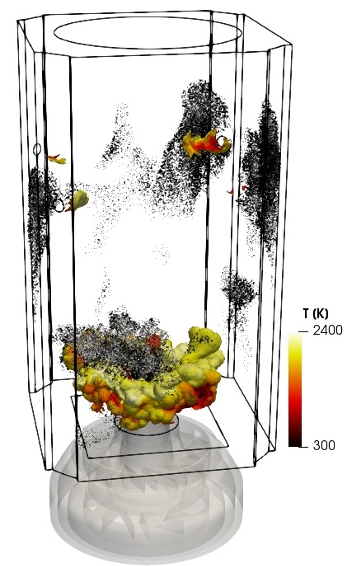

Other pollutants that one may consider when burning heavy hydrocarbons is the production of soot particles. Those molecules are harmful for health and promote the formation of contrails, that reflect the solar radiation and then create a net positive radiative forcing. The formation of those soot particles is complex, involving several steps and requires precise intermediate species prediction as well as a correct representation of the different pathways leading to the formation of soot particles.

Gallen, L.. Prediction of soot particles in gas turbine combustors using large eddy simulation. PhD Thesis. INP Toulouse – Ecole doctorale : MEGeP. 7 (2020).

Felden, A.. Development of analytically reduced chemistries and applications in Large Eddy Simulations of turbulent combustion. PhD Thesis. Ecole Doctorale MEGeP – INPT TOULOUSE. (2017).

3. Transient effects

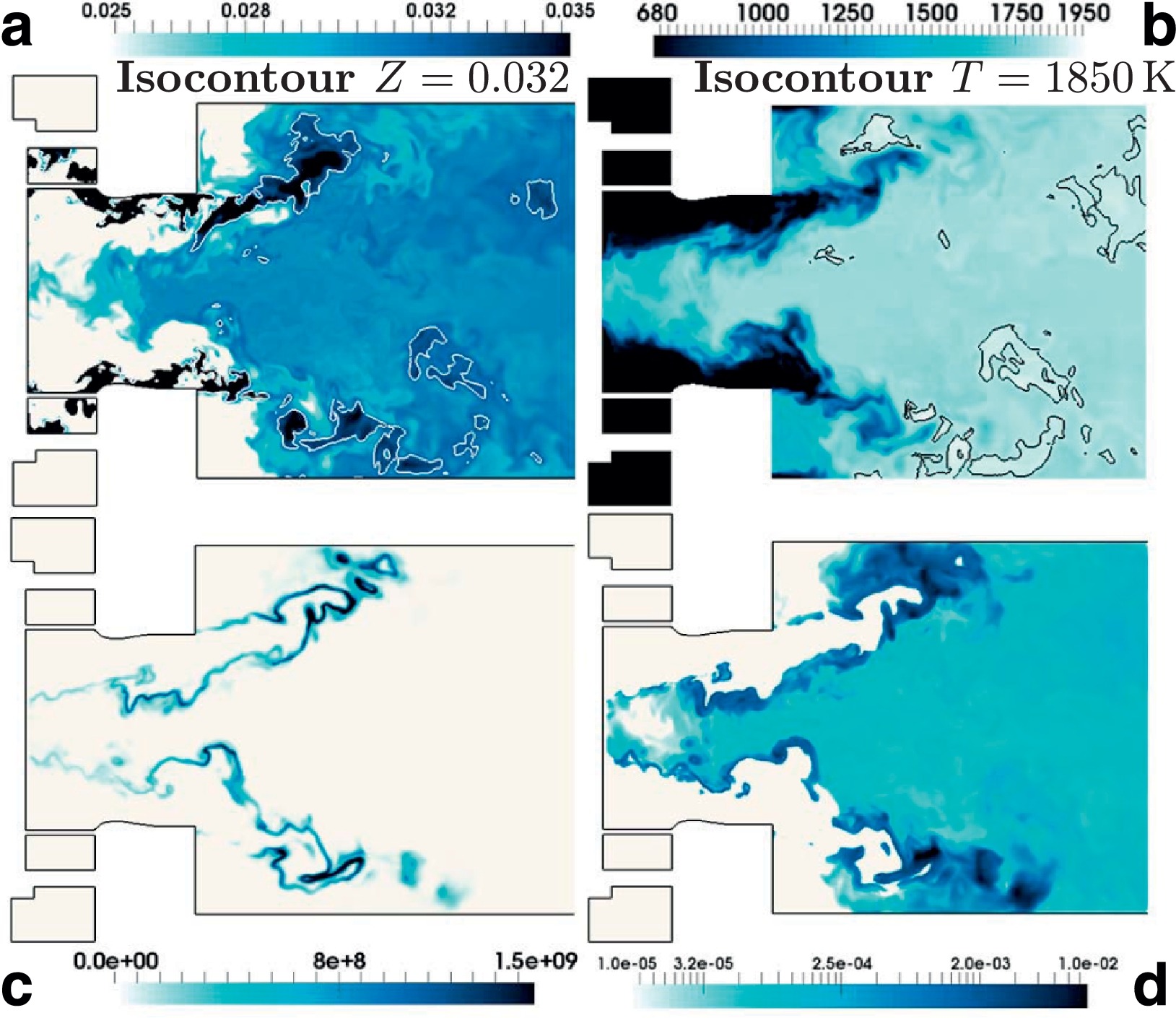

a) Acoustic instabilities

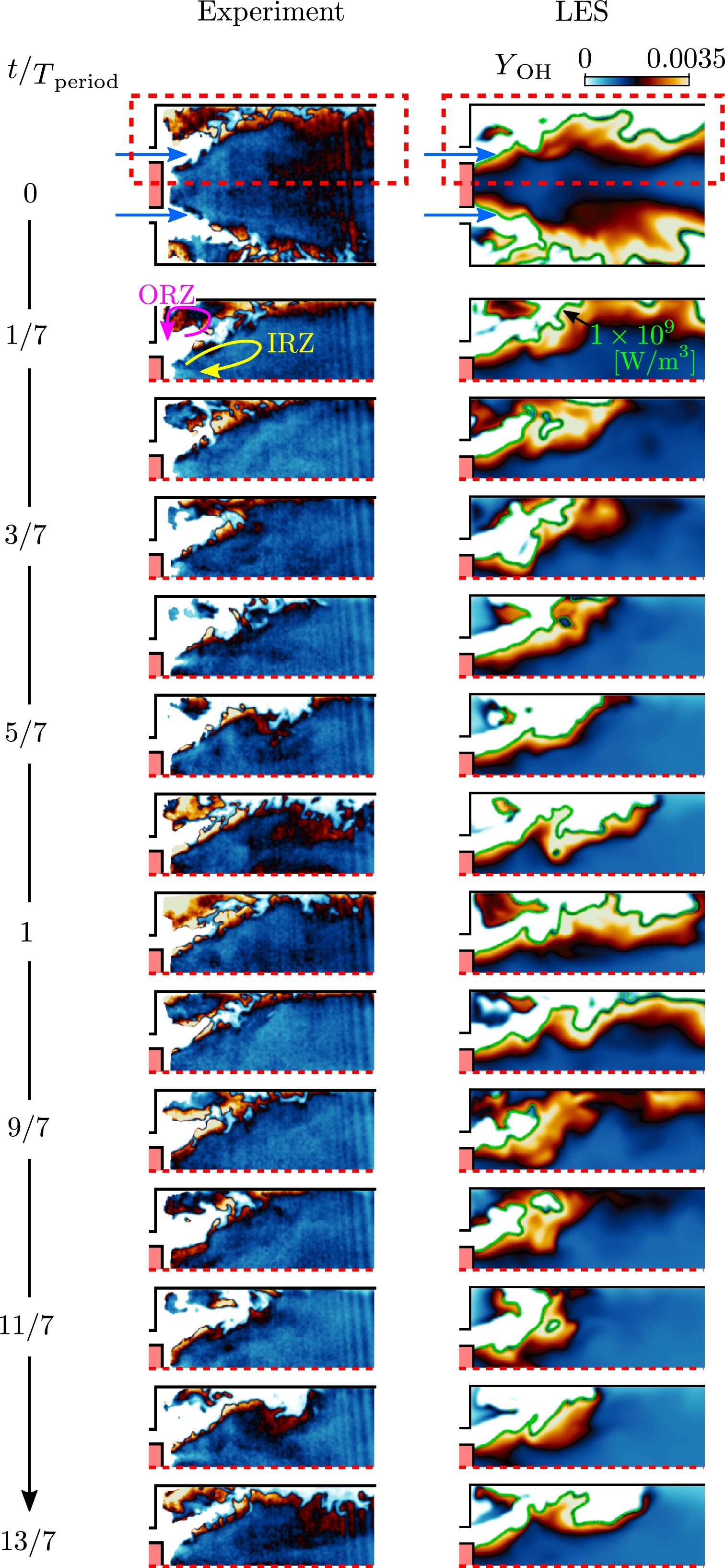

Acoustic instabilities are not desirable in an aeronautical engine as they promote flash-back and may partly destroy the combustion system. As this phenomena is coupled with the heat release rate variation, precise chemistry is required to accurately predict oscillations.

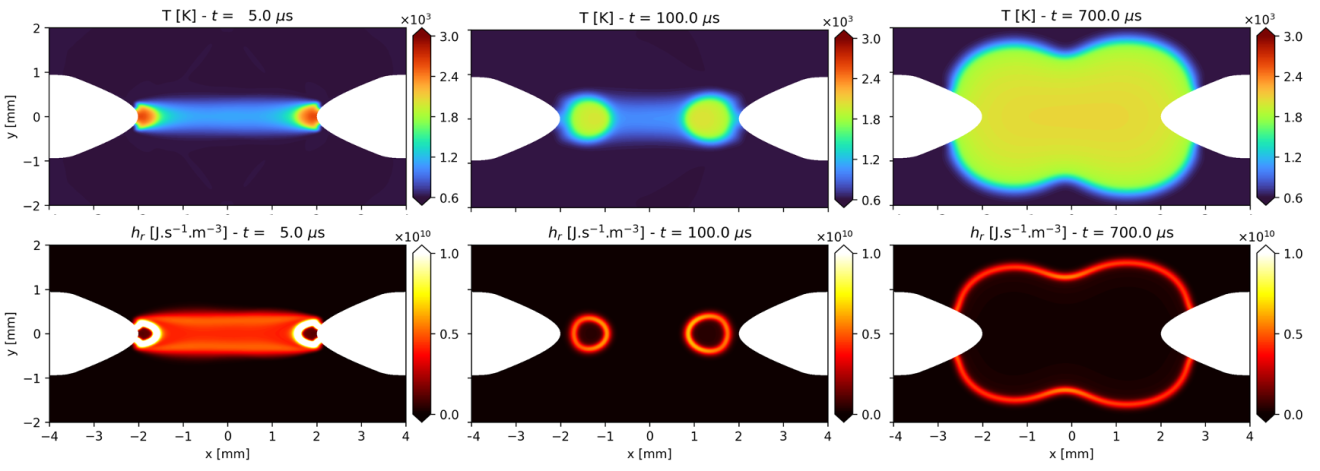

Laurent, C.. Low-Order Modeling and High-Fidelity Simulations for the Prediction of Combustion Instabilities in Liquid-Rocket Engines and Gas Turbines. PhD Thesis. Institut National Polytechnique de Toulouse – Ecole doctorale MeGEP. 6 (2020).

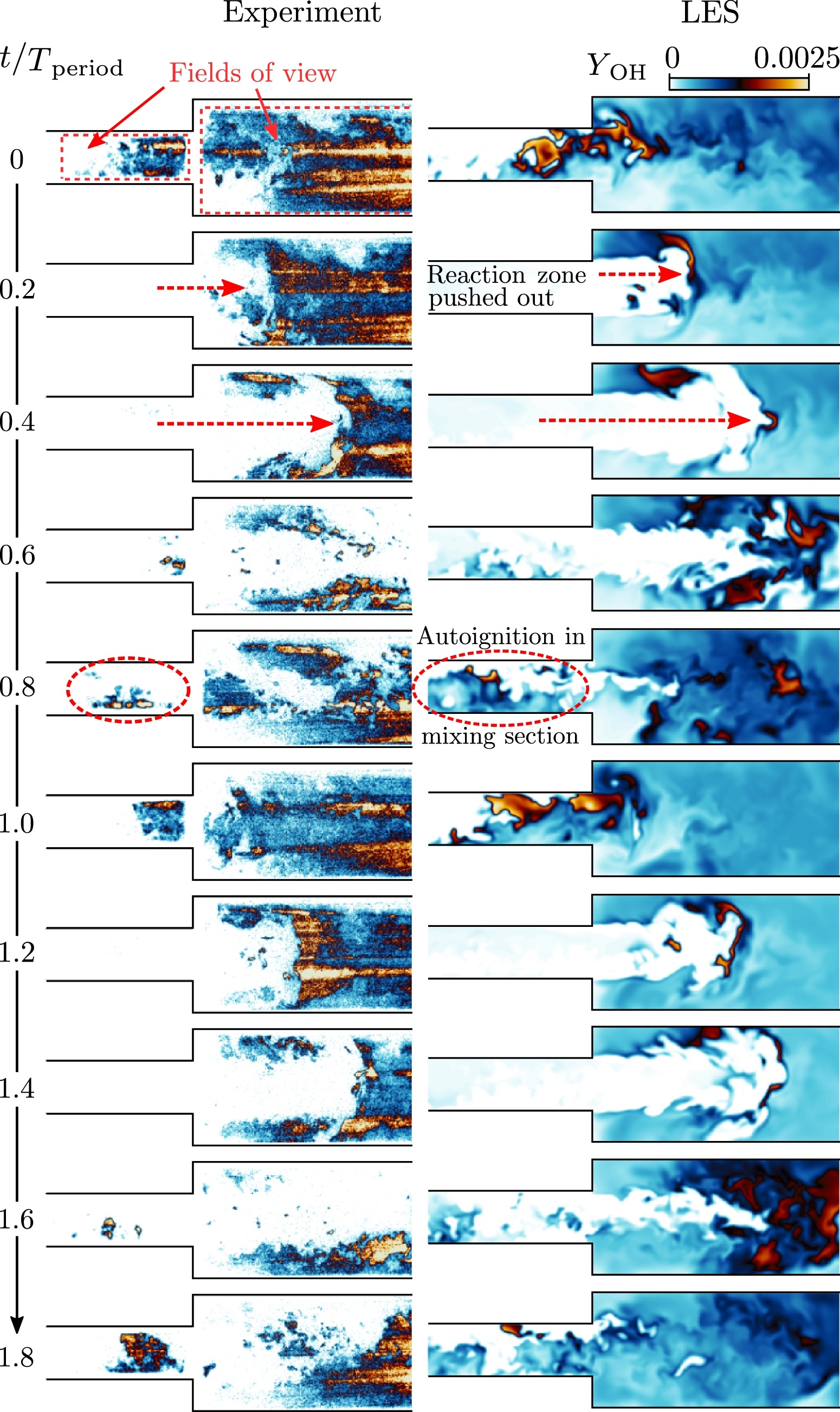

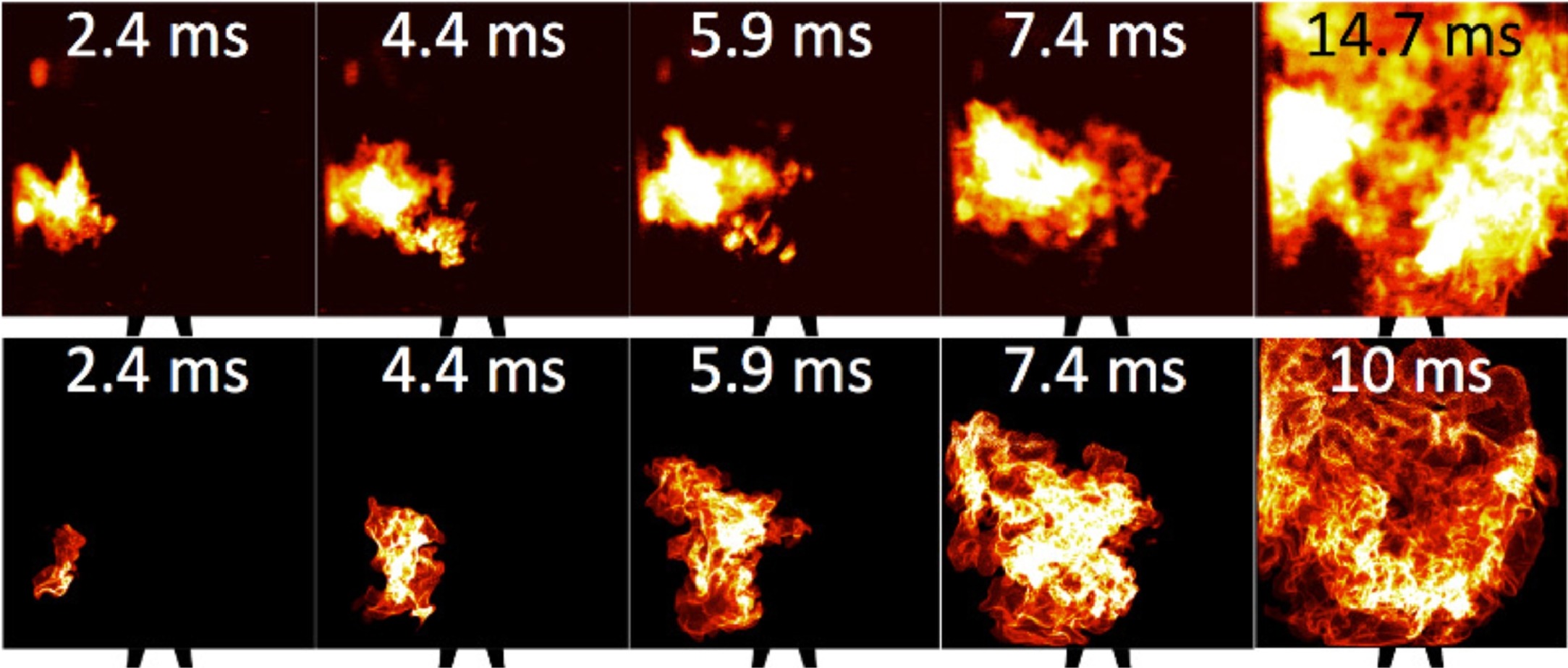

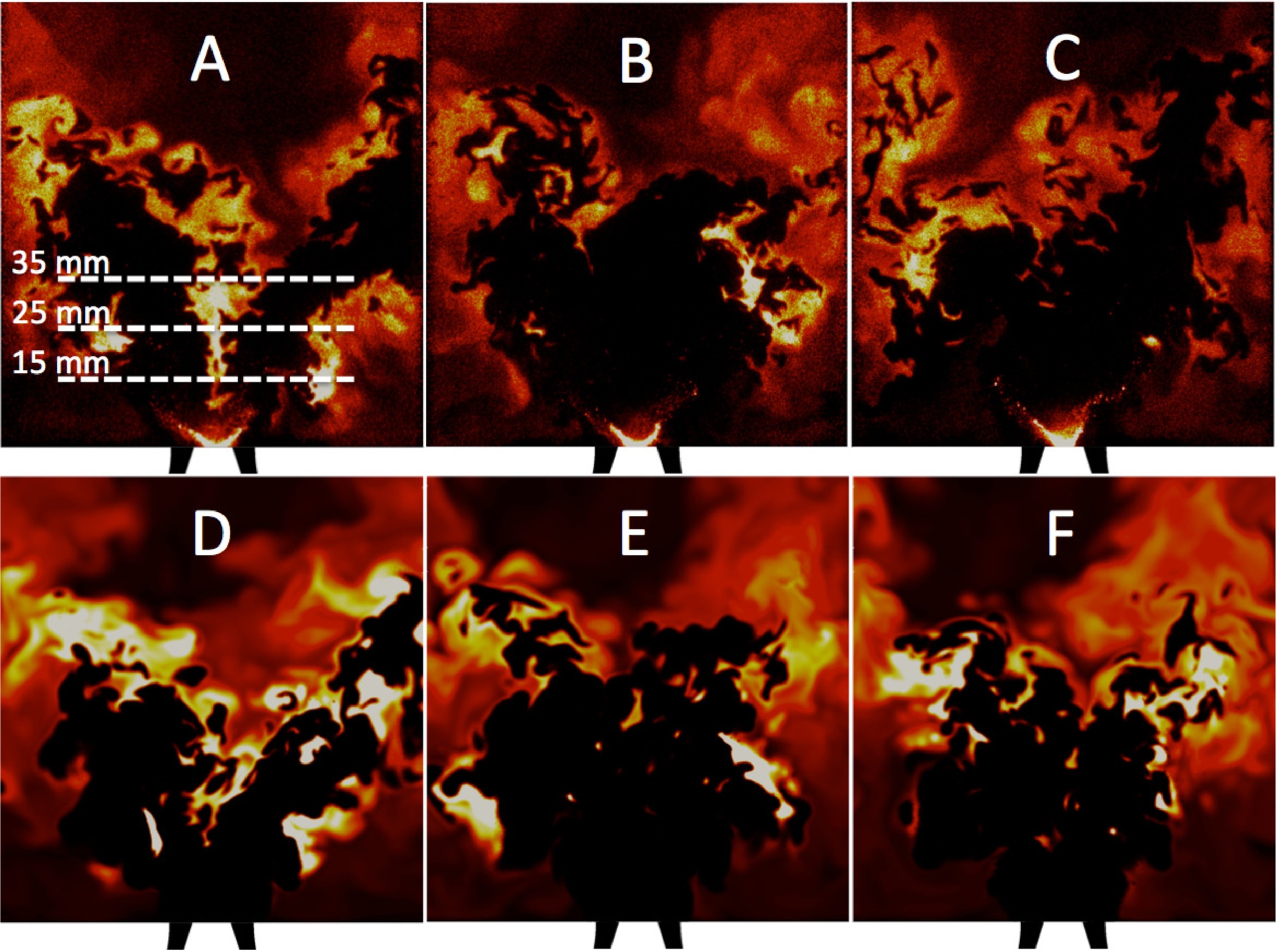

b) Ignition

Ignition is a key aspect of engines operating and safety standards. The ignition process is a transient state difficult to reproduce, since it is highly reactive, involving small scales with the flame kernel formation as well as large ones with the full ignition of the combustion chamber. Furthermore, ignition is a stochastic process which relies on several parameters such as the local turbulence, the local temperature, the energy injected, the gaseous fuel amount locally available or the liquid phase distribution with the evaporation properties. Fuel pyrolysis processes and high temperature chemical behaviors are major characteristics that must be ensured in a kinetic mechanism to reproduce correctly the ignition phase and the ignition delays.

Malé, Q.. Étude numérique de l’allumage par préchambre dans les moteurs à combustion interne. PhD Thesis. Université de Toulouse III – Ecole doctoral MEGeP. 12 (2020).

Collin-Bastiani, F.. Modeling and numerical simulations of two-phase ignition in gas turbines. PhD Thesis. Institut National Polytechnique de Toulouse – Ecole doctorale MEGeP. 5 (2019).